PCD Tipped Tooling

CBN Tipped Tooling

Bar Peeling Tools

High Speed Steel Inserts

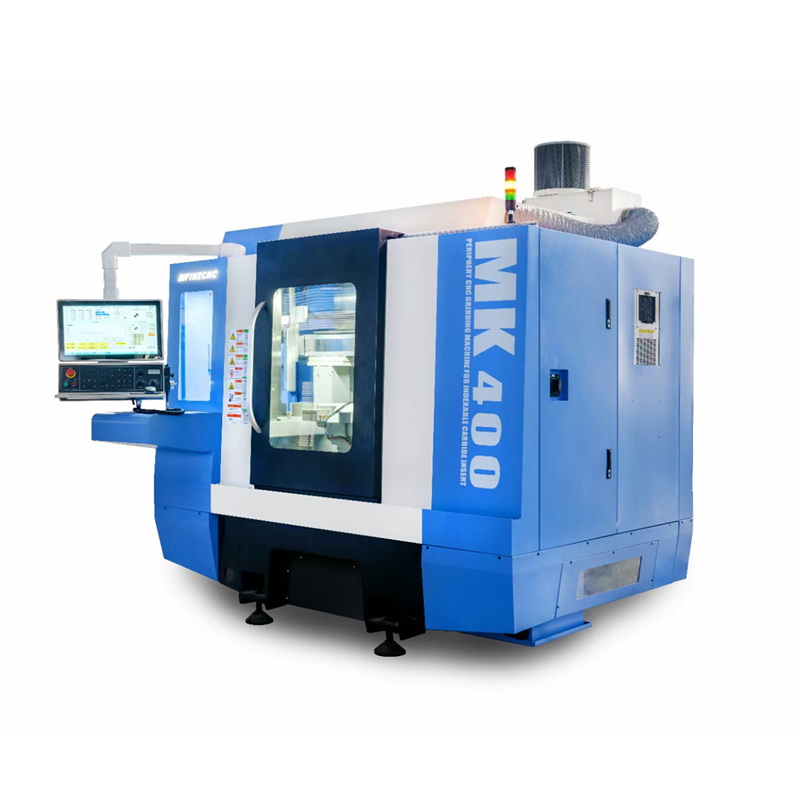

5 – Axis CNC end form grinder with MTX controls and advanced digital drive system designed for high precision end form grinding of inserts in short efficient set up and cycle times. Offering an excellent cutting edge this machine is ideal for threading and grooving inserts of any shape or size.

We produce some of the most complex “Blueprint Special” tooling. Through innovative and highly automated process engineering we can partner with customers to provide the highest quality cutting tool products at a very competitive cost per cut. We’ve invested in multi-axis CNC form grinding equipment and sponsor an in-house journeyman toolmaker-training program to insure consistent quality, pricing and reliability.

We manufacture specialty tooling for several machining applications including:

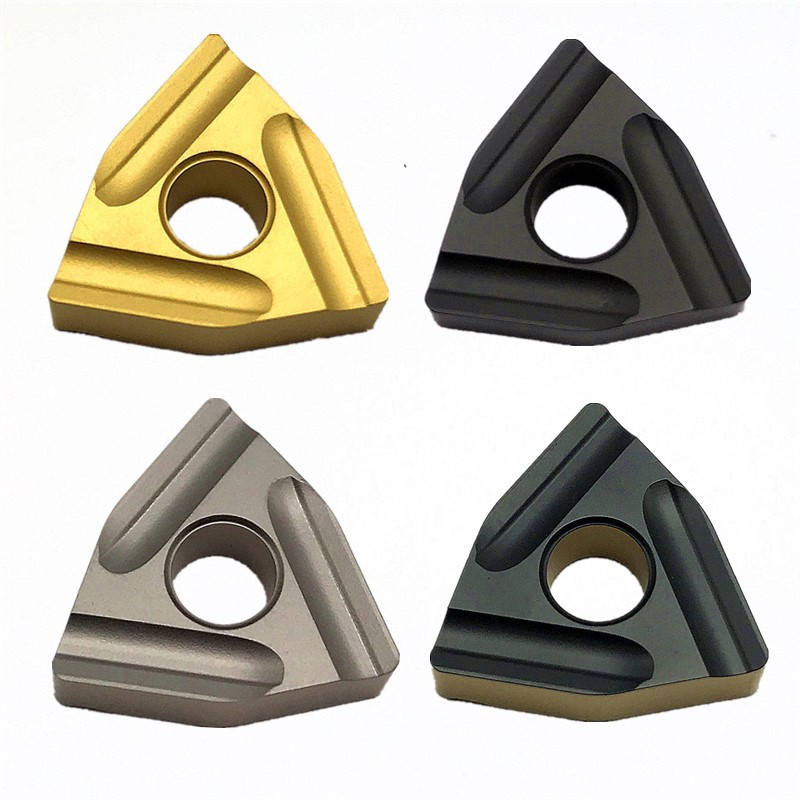

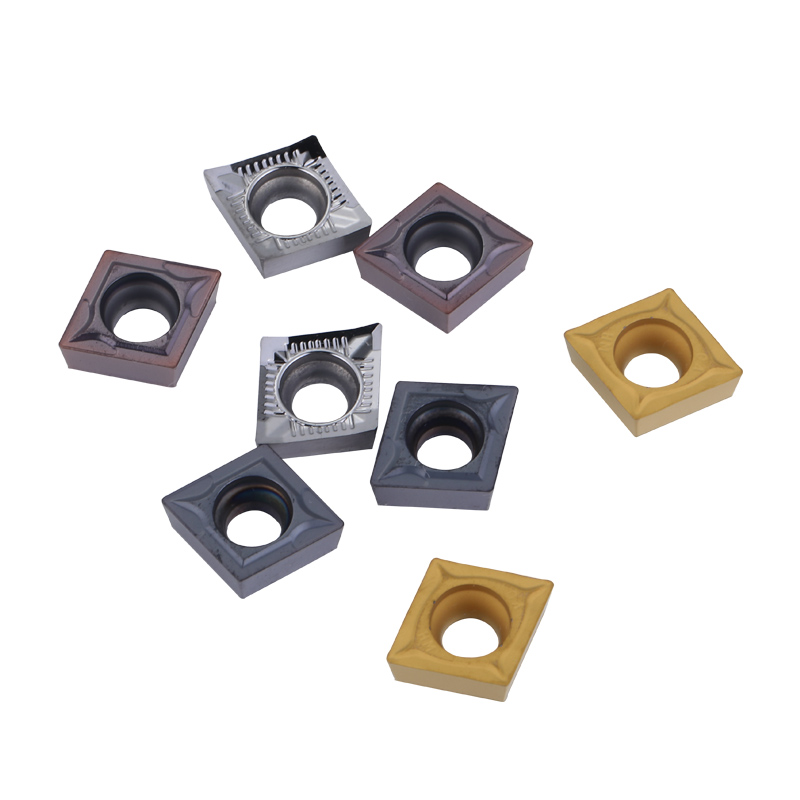

Grooving Inserts

GROOVING

carbide threading inserts

THREADING

turning

TURNING

Boring

BORING

milling

MILLING

Trepanning

TREPANNING

Burnishing

BURNISHING

Scarfing

SCARFING

5-axis CNC end form grinder is a sophisticated piece of equipment used in manufacturing processes, particularly in the production of precision components with complex geometries, such as cutting tools, medical devices, aerospace components, and more. Here's what each part of the description typically entails:

5-Axis CNC: This indicates that the grinder is equipped with a CNC (Computer Numerical Control) system capable of controlling the movement of the grinding tool along five different axes. In machining, the term "axis" refers to the direction of movement that a machine tool can control. A 5-axis CNC machine can move the cutting tool or workpiece along five different axes, providing enhanced flexibility and versatility in machining complex shapes and contours.

End Form: The term "end form" refers to the shape or contour at the end of a workpiece or component. In the context of the grinder, it likely indicates that the machine is capable of grinding the end surfaces of components to achieve specific forms, shapes, or features. This could include chamfers, radii, tapers, grooves, threads, or other complex geometries required for various applications.

Grinder: A grinder is a machine tool used for grinding, which is a machining process that utilizes an abrasive wheel as the cutting tool to remove material from a workpiece. Grinders are used to achieve high precision, surface finish, and dimensional accuracy on a wide range of materials, from metals and ceramics to composites and plastics.

A 5-axis CNC end form grinder combines the capabilities of a CNC control system with advanced grinding technology to precisely grind complex end forms on workpieces or components. By controlling the movement of the grinding tool along multiple axes, the machine can create intricate geometries with high accuracy and repeatability. This makes it an essential tool in industries where precision machining of complex components is required.

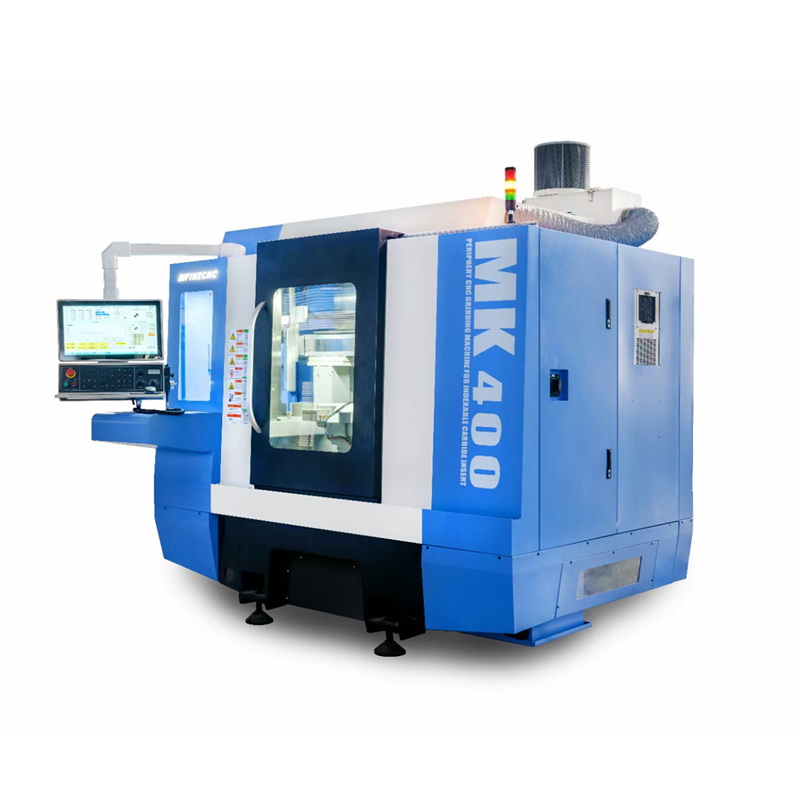

Fully Automatic Insert Peripheral Grinding Machine" is a specialized piece of equipment used in manufacturing for the precise grinding of inserts.

Fully Automatic: This indicates that the machine operates without the need for manual intervention once it's set up and started. Fully automatic machines are often used in high-volume production environments where efficiency and consistency are crucial.

Insert: In manufacturing, an insert usually refers to a small cutting tool or a component that is inserted into a larger tool or machine for specific functions, such as cutting, milling, or drilling. Inserts are commonly made from hard materials like carbide and are used in machining operations for durability and precision.

Peripheral Grinding: Peripheral grinding involves grinding the outer edge or periphery of a workpiece or component. In the context of this machine, it likely refers to the process of grinding the edges of inserts to achieve precise dimensions, shapes, and surface finishes.

Grinding Machine: This is a machine tool used for grinding, which is a machining process that uses an abrasive wheel as the cutting tool to remove material from a workpiece. Grinding machines come in various types and configurations, each designed for specific applications and materials.

Fully Automatic Insert Peripheral Grinding Machine would be designed to automatically grind the periphery of inserts to precise specifications without requiring manual intervention, making it suitable for high-volume manufacturing environments where consistency and efficiency are paramount.

5-axis CNC end form grinder can be used in a wide range of applications, including but not limited to:

Grooving Inserts: Precision grinding of grooving inserts used in machining operations such as grooving, parting, and slotting.

Carbide Threading Inserts: Grinding of carbide threading inserts used for creating threads on workpieces in turning, milling, or tapping operations.

Turning: Grinding end forms on turning inserts for applications where precise contours or features are required during turning operations.

Boring: Grinding specialized end forms on inserts used in boring operations for creating accurate holes with specific dimensions and finishes.

Milling: Grinding milling inserts with complex end forms for applications requiring intricate shapes and features during milling operations.

Trepanning: Precision grinding of inserts used in trepanning, a machining process for cutting large-diameter holes in metalwork.

Burnishing: Grinding of burnishing inserts used for smoothing and polishing surfaces of workpieces to improve surface finish and dimensional accuracy.

Scarfing: Precision grinding of scarfing inserts used in metalworking processes for removing surface defects or preparing edges for welding.

In each of these applications, the 5-axis CNC end form grinder offers the capability to precisely shape and grind inserts to meet specific requirements, ensuring high-quality results and improved efficiency in manufacturing processes.

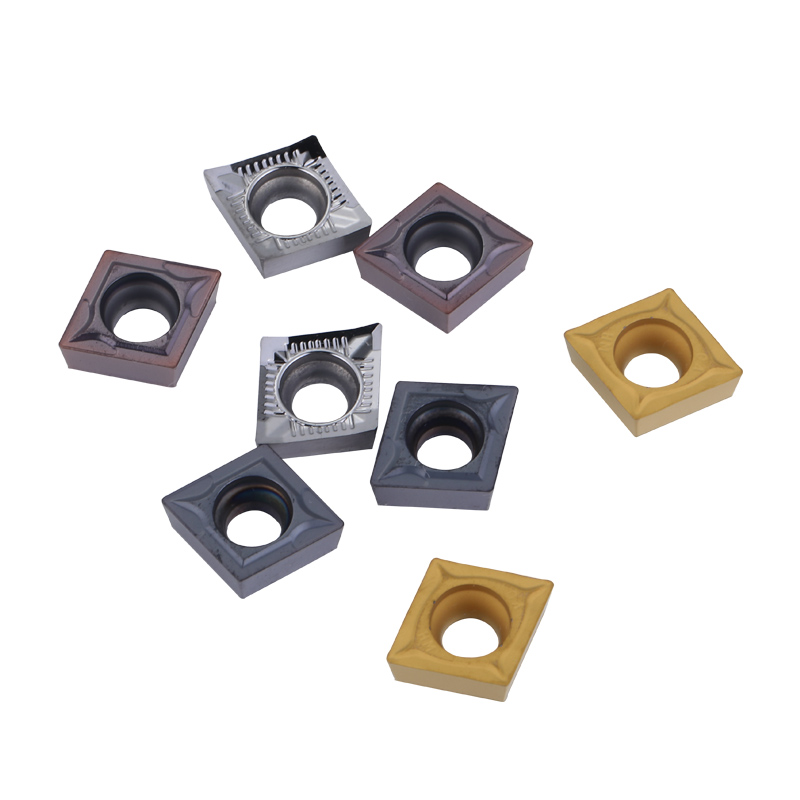

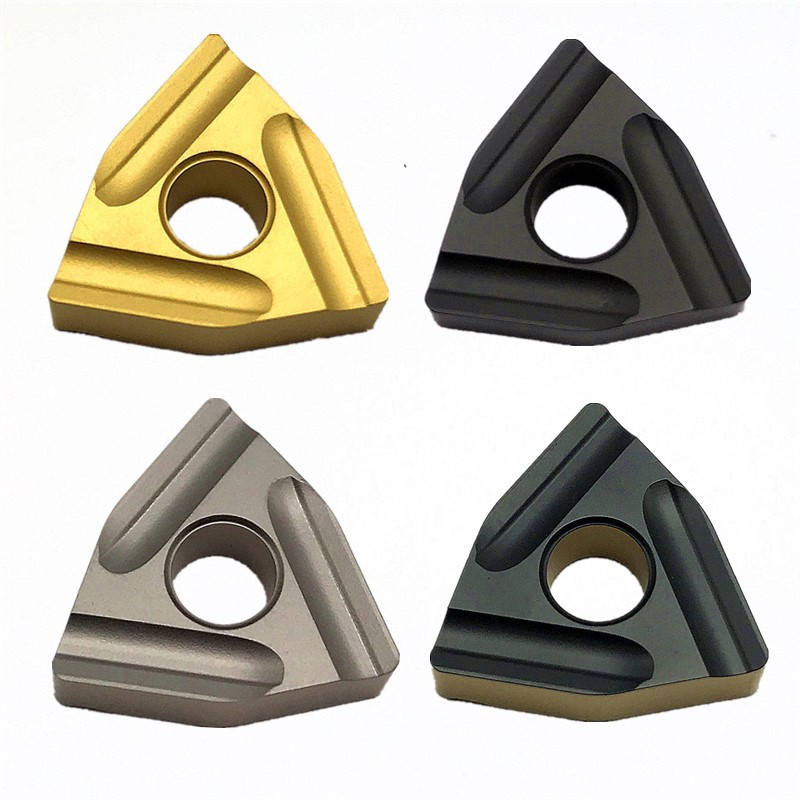

Precision Carbide Inserts and Tooling including Ceramic, PCD (Polycrystalline Diamond), CBN (Cubic Boron Nitride) CNC periphery grinder

High-precision tools and inserts used in CNC (Computer Numerical Control) machining, particularly for grinding operations. Carbide inserts are commonly used for cutting and shaping tough materials like metal alloys. PCD (Polycrystalline Diamond) and CBN (Cubic Boron Nitride) inserts, on the other hand, are known for their exceptional hardness and wear resistance, making them suitable for machining hard materials like composites and hardened steels.

A CNC periphery grinder would be a machine used for precisely grinding the periphery or outer edges of these inserts or tools to specific dimensions and tolerances. This kind of equipment is crucial for achieving the exact geometries required for efficient and accurate machining processe